The Lean Transformation of Project Industries through Project Business Automation

Reengineering the project business to reduce waste and maximize value.

Waste from Inefficiency is Core Problem

All project-based companies share many of the same core common business processes. As a result, they also share the major common business problem – waste.

Project companies are plagued with massive waste in the form of inefficiencies due to:

- Disjointed and misaligned processes

- Lack of visibility

- Lack of accountability

This waste leads to inflated costs that take the shape of budget buffers and large amounts of float/slack.

Why the Inefficiency?

Inefficiency and waste in project-based companies stems from their siloed architecture. They are so separated that the different functions and departments inside the enterprise behave almost like different companies.

These organizational silos lead to and are many times enabled by system silos (such as different systems for ERP, project management and project accounting).

This structure means that the data is siloed as well. Therefore, it is difficult to transport, correlate and visualize this data to help the companies operate faster and make better decisions.

Learning from History

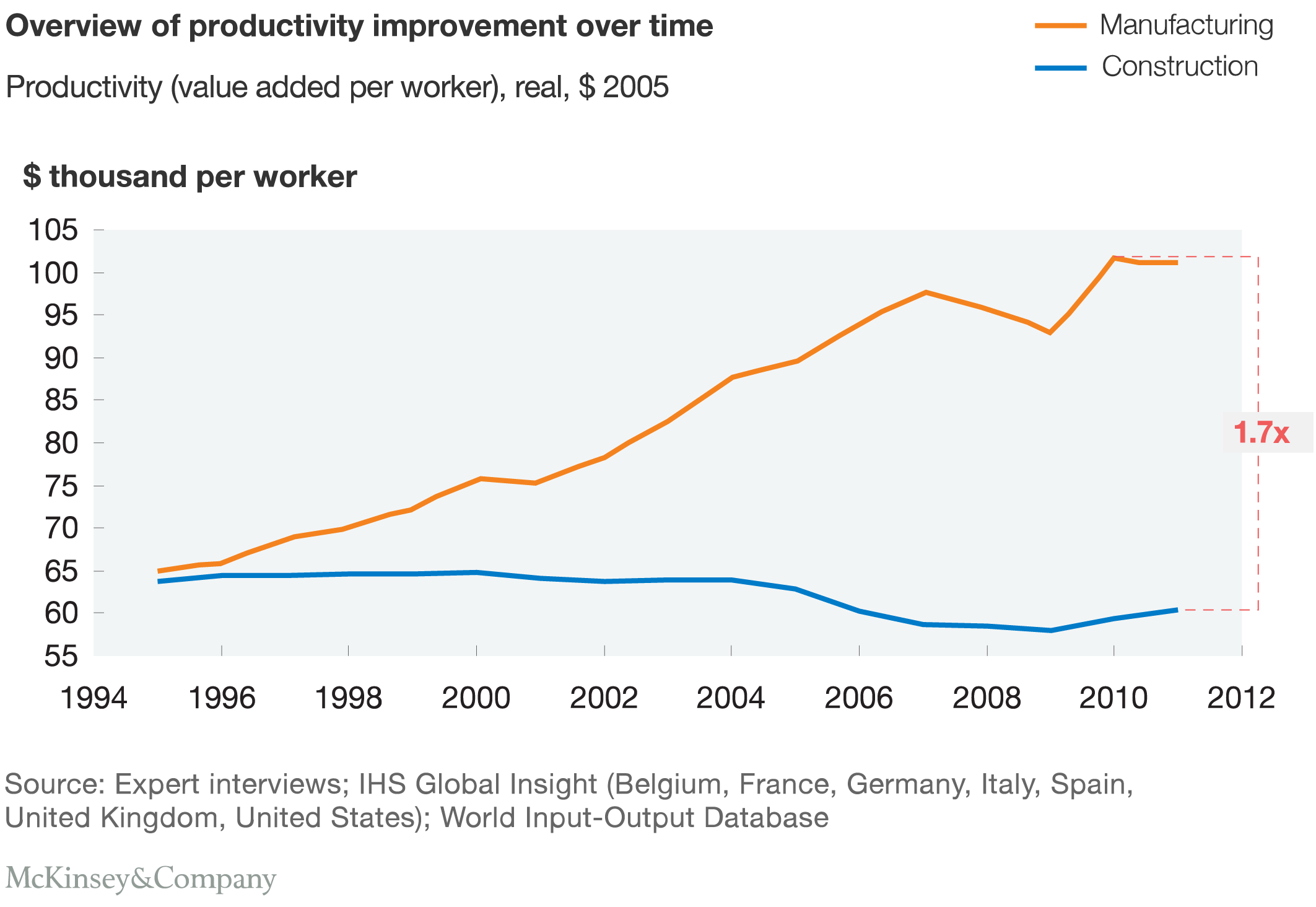

If we look to other industries, such as manufacturing, we see that the problem of waste reduction has been tackled already by Lean Management theory.

The introduction of Lean Manufacturing and MRPII in the early 1990s led to significant improvements in productivity. MRPII, which later became the major component of ERP, was a key factor in enabling Lean Manufacturing to take hold. MRPII broke down the system silos and unified the organization that allowed for unprecedented visibility and process alignment.

How We Apply Lean to Project Industries

with Project Business Automation

Process Reengineering the Project Organization

We need to apply lean thinking to the entire enterprise, and not just one of the silos. Many of the "lean" attempts we have seen for projects have been applied only to the project operations side of the company, ignoring the financials. Applying lean to the company as a whole is the only way we can break down the silos.

What Project Business Automation accomplishes:

Realign functions and departments across the company. Create connections where there were none before.

Automate Processes

Automate and optimize processes to eliminate waste.

Increase Visibility

Unprecedented real-time visibility means you respond faster to changes and speed up decision making.

Enforce Best Practices

Reduce risk and ensure quality through systematized process control.

Project Business Transformation Results

Removal of Inefficiencies

- One source of truth for better alignment

- Automated rule-based workflows eliminate waste between process steps

- Real-time visibility to monitor portfolio performance

- Increased agility to respond to change more effectively

- Enforced best practices to remove process variations

Improved Decision Making

- Identify bad news early to reduce or eliminate risk before they manifest

- Reduce variations in quality, time & cost

Increased Accountability

- Greater control with improved process governance

- Learn from mistakes with clear process responsibilities

ADEACA ONE Project Business Automation for the Lean Project Enterprise

We created ADEACA ONE Project Business Automation as a system to facilitate the lean transformation of project businesses. It breaks down the silos and creates a new structure for your organization to achieve breakthrough productivity.